Teaching students to work in the field

«TESTING THE CAR PARTS»

Main areas of work:

1. Details of internal combustion engines

|

|

|

| Pistons and cylinder liners | Piston rings and valves |

2. Details of automobile breaking system

|

|

| Brake discs and drums | Breaking pads |

3. Components of the suspension and steering gear

|

|

| Weights, heads and arms | Slient-blocks |

|

|

|

Spring and springs

|

Plug items |

Types of tests:

|

|

| Measurements of strength | Measurements of hardness |

|

|

| Tolerances measurements | Analysis of product defects |

|

|

Measuring the strength of brake pads with cut

|

|

Measuring the brake pads at elevated temperatures

|

|

|

Measurement of the elastic rubber-metal joints

|

|

|

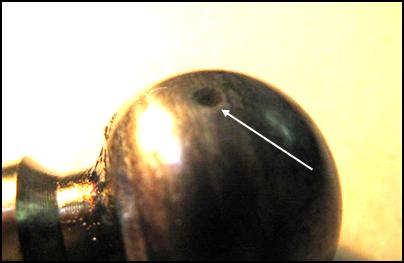

Research of crankshaft defects

Testing the camshaft

Braking systems research

Measurement of hardness of metal parts

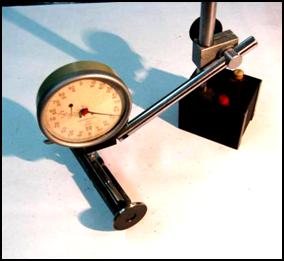

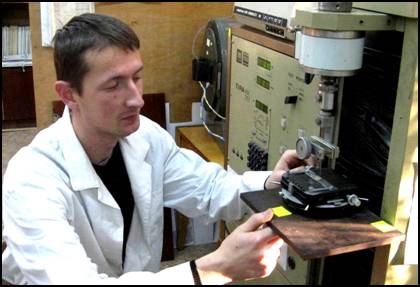

Equipment in which students study and perform research work:

1. Electronic universal testing machines TIRA-test series

2. Measuring instruments and tools (Cathetometer, watch indicators, micrometers, calipers samples roughness, etc.)

3. Dynamometers and hardness measuring devices

4. Metallographic and counting microscopes

5. Laboratory and analytical weights

6. Other equipment

Materials and products for research work:

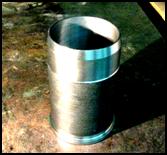

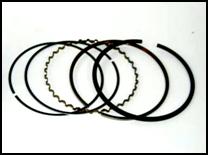

Details of cylinder - piston engines:

Piston rings and compression masloznimni

Pistons for automotive and tractor engines

Piston Pins

Cylinder liner for automobile engines

Details of engines gas distribution mechanism

Details of engines crank mechanism

Elements of suspension and steering gear

Brake system elements:

Brake pads and linings

Brake disks and drums

Sheet springs and coil springs

Wheel mountings

Plug elements:

Ball Pins

Kingpin

Pins

Inserts

Feed rubber sealing parts

Coupling Discs. Wheels gates